In this blog, we’ll explore the Best Practices For Preventing Explosions In Hazardous Areas

Ramdas, an author with glorious prestige, has delivered a masterpiece here, with more than 20 years of professional service. He has excelled in the field of flameproof equipment manufacturing. Also, he has mastered the art of designing and developing custom flameproof solutions to meet distinctive industry requirements. He has channeled his deep expertise in this blog through a broad range of applications, like the hazardous environments in the chemical and petrochemical sectors.

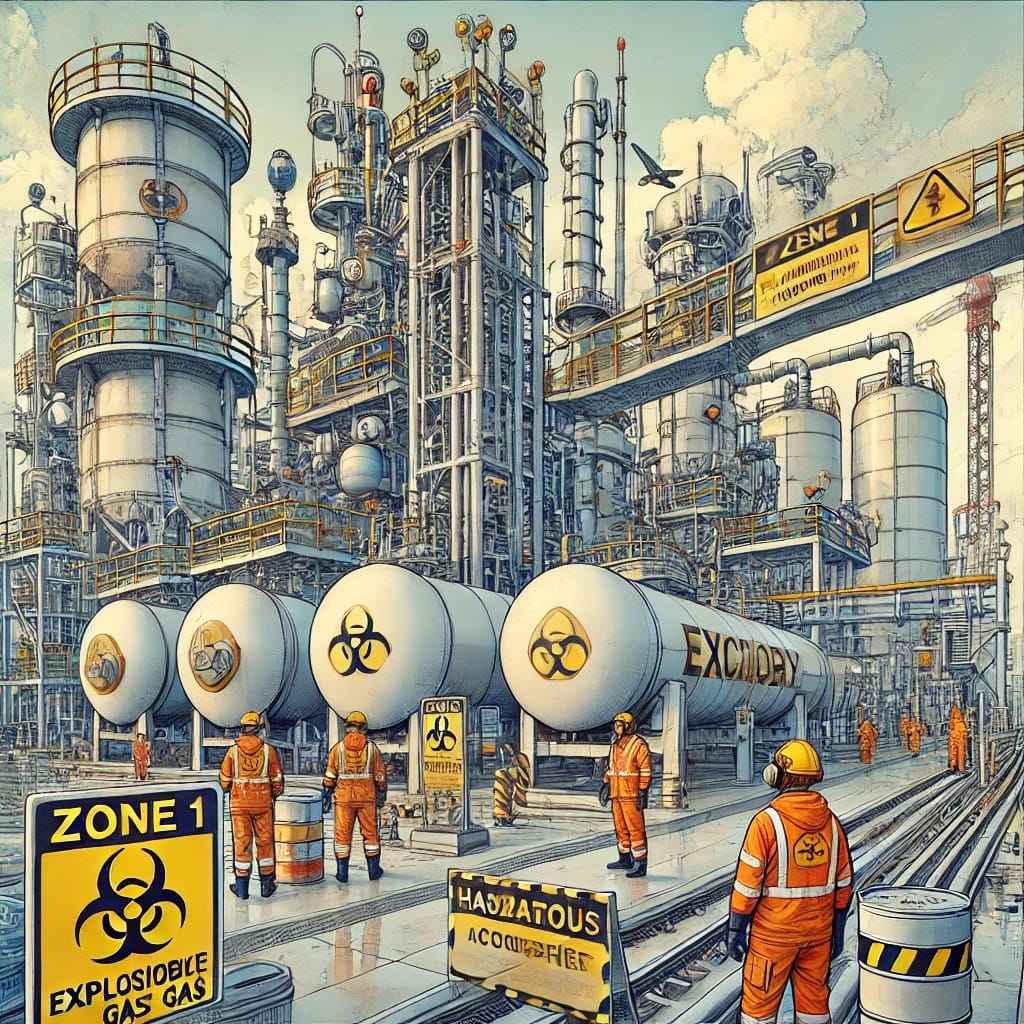

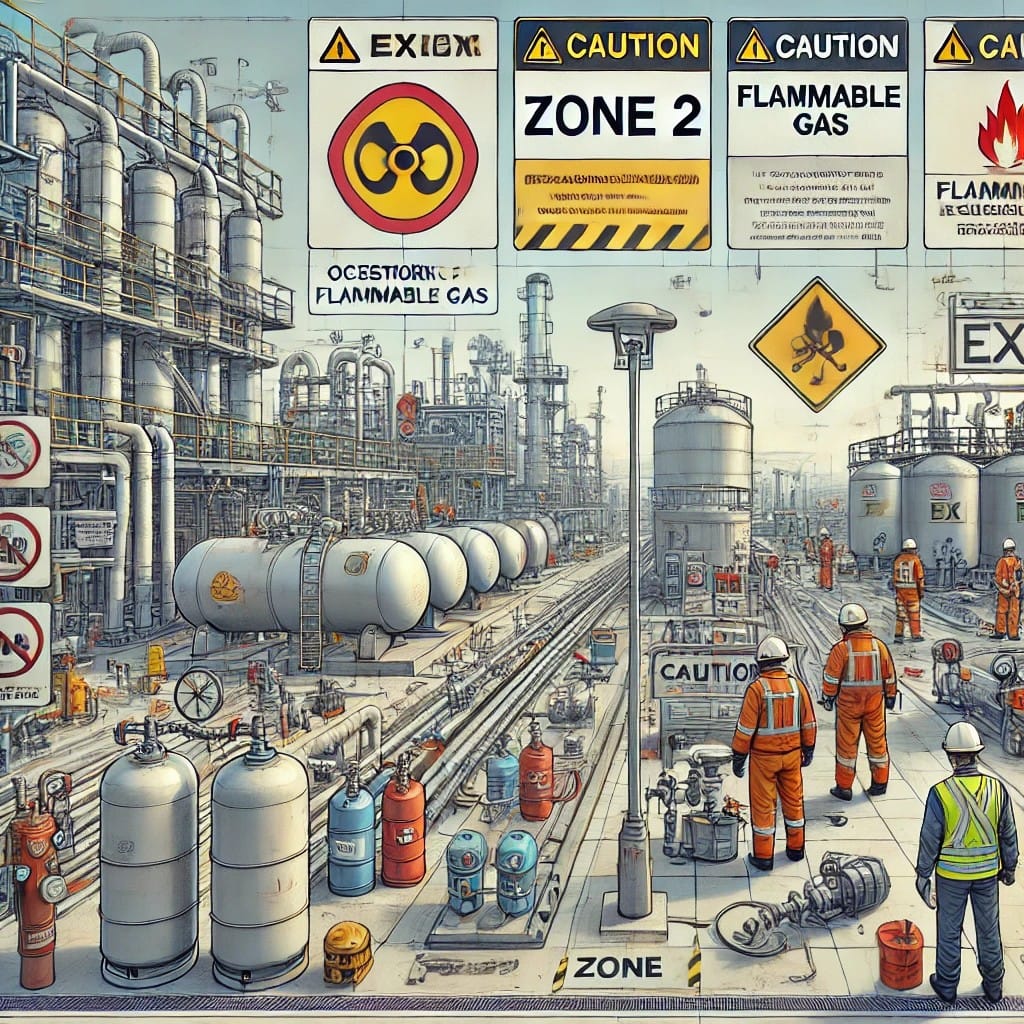

As the name suggests, ‘hazardous areas’ are just what you feel them to be: places with significant risks of explosions due to the presence of flammable gas, vapors, or dust. These areas are widespread in sectors that deal with oil, chemicals, pharmaceuticals, and manufacturing. We will also not be wrong to say that hazardous areas might be catastrophic in their ways. The Directorate General Factory Advice Service & Labour Institutes (DGFASLI) recorded approximately 1,000 dangerous occurrences and 988 fatal injuries in 2020-21 among the many factories in India.

The consequences of any happenings here are dire, like loss of life, fatal injuries, environmental degradation, and loss of property. So, it becomes our duty to opt for ‘explosion-proof’ ways to deal with such issues, like ensuring workplace safety and controlling workplace overpressure. The National Fire Protection Association has alarmed us by stating there was approximately $14 billion worth of property damage due to industrial fires, including high-end explosives. So, it becomes our duty to understand the concept of hazardous zones to the very core and bring about measures to level down their impact.

Marching Through The Hazardous Zones

Hazardous areas are treated as those zones that mark the presence of explosive atmospheres in high quantities, thus requiring special precautions to be undertaken. Classifying distinct hazardous zones counts as separating the areas on the basis of the occurrence and duration of an explosive gas environment.

1. Zone 0

Here, an explosive and thus, threatening environment is present continuously or for a prolonged period. An area can be classified under Zone 0 if it constitutes the presence of an explosive atmosphere of more than 1000h/year. Here, the flameproof equipment must be highly reliable and designed to endure heightened conditions of explosive surroundings. Explorations, drilling operations, refineries, and petrochemical plants can be parts of this zone.

2. Zone 1

Once an area hits Zone 1, it is in the arena of not-so-intensive explosive atmospheres. Here, the explosive atmosphere is between 10 to 1000h/year. Equipment and best practices for flameproof methods must be curated to prevent ignition under normal conditions. Applications of the oil and gas industry, production and handling of chemicals, underground mining operations, pharmaceutical production, and many others are parts of Zone 1.

3. Zone 2

Zone 2 can be a safe one in comparison with others, as here, an explosive atmosphere is usually not likely to prevail in normal conditions. If it does, it will be only for a short period. Also, the explosive environment here prevails for not more than 10h/year. The explosion proof lights must be designed keeping in mind the fact to avoid ignition sources. There are distinct industry applications of Zone 2- like production and handling of chemicals, processing plants, processing and packaging operations, and the list goes on.

Understanding Risk Assessment & Hazard Analysis

Opting for flameproof measures when you are faced with explosive environments is critical so as to avoid catastrophic consequences. So, let us dig into the crucial steps of assessing the risk and analyzing potential hazards that can prevail in explosive areas.

Undergoing Hazard Analysis

The primary goal of conducting a hazard analysis is to identify potential areas where explosive environments can be present. Here, you have to gain thorough knowledge about the types of materials handled, processes used, and others. Once you have identified the source, it becomes crucial to evaluate all possible sources of ignition and assess factors like ventilation, temperature, and the presence of potential explosives.

The US Chemical Safety and Hazard Investigation Board has found that more than 70% of major industrial mishaps are the result of improper hazard analysis. So, flameproof enclosures are designed keeping in mind the prevention of ignition. Also, flameproof lights come in handy for withstanding explosions and eradicating ignition.

Determining The Probability Of Explosions

In the step after hazard analysis, you have to keep track of how hazardous materials are present in the atmosphere. After doing so, one must assess the dire risk impacts and severity they possess. Evaluating the future outlook must be backed by reviewing past accidents and safety reports to ensure that what has happened before does not repeat itself. Purged and Pressurized Enclosures help create a protective and flameproof panel against hazardous environments.

Establishing A Risk Management Plan

The critical preface in setting up a risk management plan is implementing safety protocols like installing flameproof products, enhancing ventilation, and using non-sparking tools. Keep the personnel and other workplace members informed about the potent risks and scope of explosive environments through training programs.

Curate Standard Operating Procedures (SOP) to take control of unforeseen circumstances and get hold of an emergency response plan. Flameproof Junction Boxes will do the trick here. The International Organization for Standardization denotes that a vital risk management plan has helped reduce explosive incidents like this by up to 30% in hazardous industries.

Implementing Safety Equipment & Controls

Explosion Proof Equipment

An explosion-proof equipment is curated to contain any explosion within the device and prevent it from igniting the environment. This is typically used in areas exposed to industries like refineries, mining operations, and chemical plants. Such equipment includes explosion-proof enclosures, explosion-proof lights, motors, and pumps.

Intrinsically Safe Equipment

Intrinsically safe equipment operates at energy levels that are not enough to ignite an explosive background. This helps eradicate the risk of ignition and is most suitable for areas facing low concentrations of explosives. Intrinsically safe sensors and instruments, as well as communication devices, will come in handy to monitor environmental conditions without risk of sparking.

Ventilation Systems

The primary purpose of installing ventilation systems is to remove or dilute harmful gases and vapors, thus contributing to a safer, explosive-free atmosphere. These should be installed in confined areas, process spaces, and storage substances that house flammable products. Local exhaust ventilation, supported by a general ventilation system, assists the fireproof equipment by eliminating contaminants directly from the source, like fumes from a chemical operation.

Gas Detection Systems

Installing a gas detection system is crucial in closely monitoring the concentration of hazardous fumes and providing early warnings of any mishaps. They are specifically used in areas where toxic gases exist, like storage tanks and confined spaces. Fixed as well as portable gas detectors are used to assess any gas leaks or accumulations in various areas.

Electrical Isolation And Grounding

Electrical isolation assists in preventing circuits from coming near hazardous areas, thus lowering the risk of shocks. Also, grounding is done to discharge hazardous areas from electric faults and static charges safely. This, in turn, helps reduce the risk of ignition in dangerous spaces. Isolation transformers and barrier devices do the deed of protecting against electrical hazards and much more.

Explore the applications of various flameproof products in our detailed blog.

Tips To Ensure Safety Prevails In Hazardous Areas

Proper Storage & Handling Of Flammable Materials

The first factor to keep in mind is to make use of explosion-proof containers that are specifically prepared for flammable substances. These must also comply with adequate safety standards and should be labeled clearly. Flammable substances must always be stored in thoroughly ventilated areas and must be kept away from potential sources of ignition.

Effective Training And Awareness

Employees must be thoroughly trained on the safe handling of potentially hazardous substances through training programs and seminars. Equipment must be regularly checked, along with storage areas, to make sure they are hazard-free. Safety areas like flameproof ventilation and gas detection systems must be thoroughly scrutinized to support adequate functionality.

In Accordance With Regulations And Standards

Be well aware of safety standards and regulations like OSHA, NFPA, and others. Regular audits and best practices must be regulated to ensure safety, equipment design, and other crucial factors. Develop an Emergency Response Plan that outlines processes for various types of accidents- like explosions, chemical spills, and others.

Make Safety From Disastrous Explosions The First Lookout

As we have mentioned above, hazardous areas and explosives are too essential to be treated lightly. So, get your hands on top-notch and durable flameproof lights, alongside other crucial equipment, to stay miles away from catastrophic dangers. To get the quality equipment for preventing these hazards, Bharat Flameproof offers an exquisite list of equipment. Rely on the best in the world of flameproof equipment to get hands-on deals for ensuring safety. Commit to proactive processes and safety measures to solidify protection from disastrous hazards of different industries in an instant!