Introduction

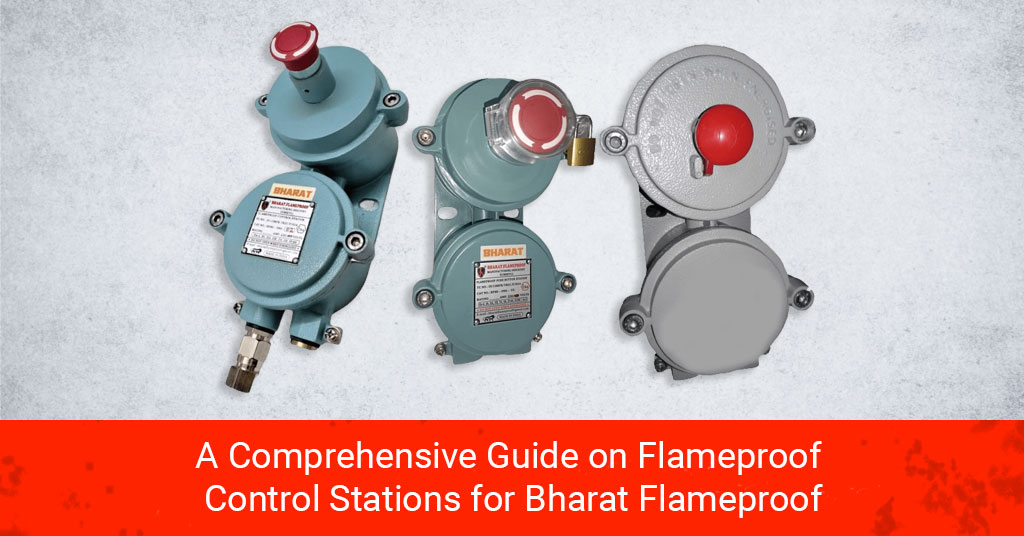

In this blog, we’ll learn about flameproof control stations, safety standards, benefits, and industry applications, ensuring protection for workers and assets in hazardous environments.

Establishing high standards for welding is important exclusively within gas and air welding procedures. Having secure control rooms should be considered when considering safety in this kind of setting. These systems are designed to activate safety measures promptly in a blast accident/incident at the control station. This guide aims to highlight the rules, laws, and benefits of explosion-proof control stations. This will help protect workers and property from a variety of risky environments.

Explaining Traditional Control Stations

However, the previous analogue control rooms were for the safe industrial plant work location in a stable city region. They may need more advancements to undertake the most severe threats. Control rooms are responsible for hazardous gas or vapour in petrochemical facilities, refineries, and other chemical process activities since they may increase accident risk. Installing electrical controls within the station without shielding might cause biomaterials nearby to catch fire. The calamity may cause significant and devastating effects.

Principles of Flameproof Design

People work in flameproof control stations to protect from fire flames. Plan to employ non-explosive materials like fuse covers at the impact location. The control posts protect against fire, so sparks and flames can’t get into space and ignite. These non-explosive materials around the explosion should be able to handle the force of the explosion and any blast conditions without breaking.

Safety Standards and Regulations

Most importantly, flameproof stations follow all safety rules and guidelines. The company needs to follow precise instructions from oversight groups. When it comes to explosion-proof tools, these rules cover specific issues. For example, the guidelines cover how the tools should be designed, built, and tested, all of which help to lower the risk. These guidelines indicate they care about worker safety and don’t injure anyone.

Benefits of Using Flameproof Control Stations

Flameproof control stations offer essential safety precautions for safe operations in hazardous situations. First, analyse the benefits to determine how they’ll streamline your processes.

Enhanced safety: Stations resistant to corrosion demonstrate that sparks will not occur in the air when subjected to greater temperatures and increasing pressures.

Disaster prevention: By stopping sparks and fires from getting into the environment, the gadget will lower the chance of disastrous events.

Regulation compliance: An intense command centre allows the company to meet regulatory criteria and follow law enforcement security protocols.

Demonstrating commitment to safety: In addition to utilising fire-resistant materials, acquiring fire-resistant equipment can also indicate an organisation’s commitment to protecting its employees in the workplace.

Personnel and asset protection: Flameproof panels reduce ignition and accident damage to control stations, protecting personnel and their valuable assets.

Safeguarding reputation: Safety regulations and the issuing of flame-proof gear will maintain the mining organisation’s integrity and maintain its best reputation within the industry.

Long-term cost savings: However, more money will be spent on the first outfit to put off the fire, but this does not raise the expenses because preventing fires and with quick closure and liabilities leaves the same amount afterwards.

Industry Applications

Anti-flame cabinets are used in several sectors worldwide; let’s examine their applications.

- Oil and gas industry: The most preferred equipment for stable process and occupation control is flare, which deals with flammable products and direct general vehicle operations in refinery and drilling facilities.

- Chemical processing: The control centres are pivotal to their work as they are the spots where the safe usage and management of combustible substances for warehouses or facilities with a high risk of fire or explosion can be controlled.

- Pharmaceuticals: There are flameproof control stations in pharmaceutical production centers that make sure that everything is controlled automatically and according to the rules. Hence, encouraging safety measures that protect both workers and equipment.

- Mining: Control stations for plant or factory facilities are installed in mine working regions to assist risky machinery in operating in environments contaminated with flammable gases, dust, or fires.

- Manufacturing: Many industrial jobs in transportation, communication, electricity, distribution, and generation require flameproof control stations in machinery and processes involving hazardous materials.

- Power generation: Flameproof controllers monitor gas and vapour combustibles in power plants, including biomass and coal-fired fossil fuels.

- Transportation: To compensate for gasoline leaks, fireproof control stations, including tunnels and railway stations, are installed on transportation infrastructure.

Conclusion

Communities can effectively prevent burning accidents by studying and following fireproof design principles and safety rules, as well as purchasing fireproof devices. This protects people and property. Flameproof control stations are an absolute need in potentially hazardous environments. Nevertheless, these technologies are impermeable and trustworthy and perpetually fulfill the industry’s requirements, which guarantees the protection of the users.