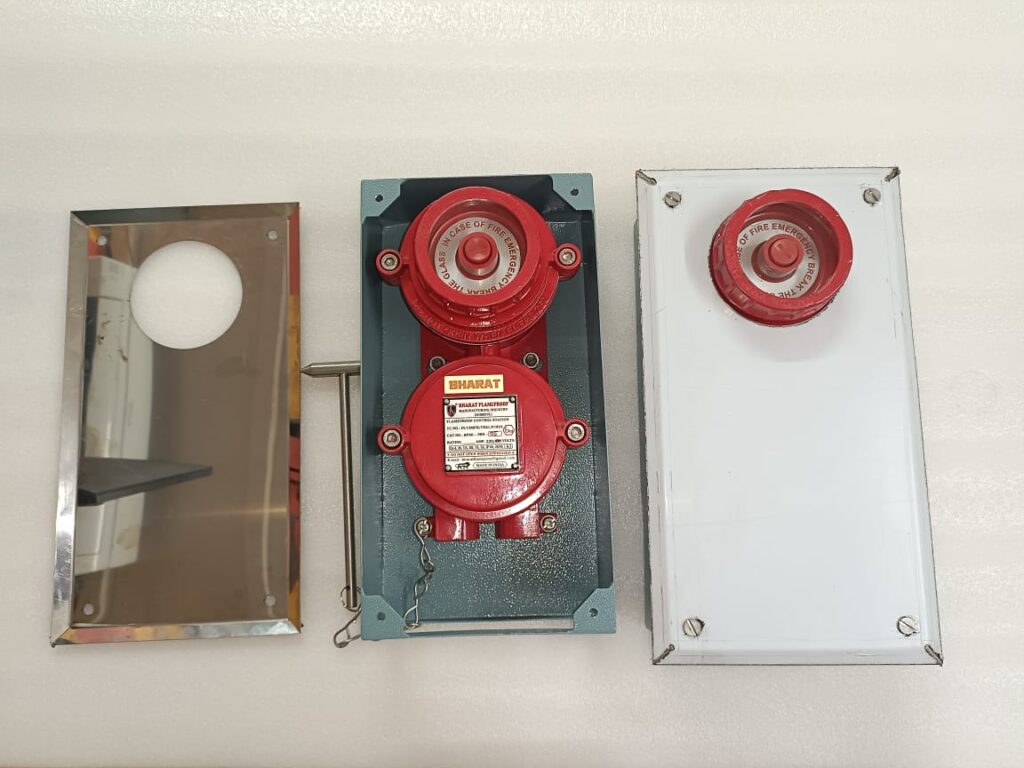

Flameproof Control Stations

What are Flameproof/Explosion-Proof Control Stations?

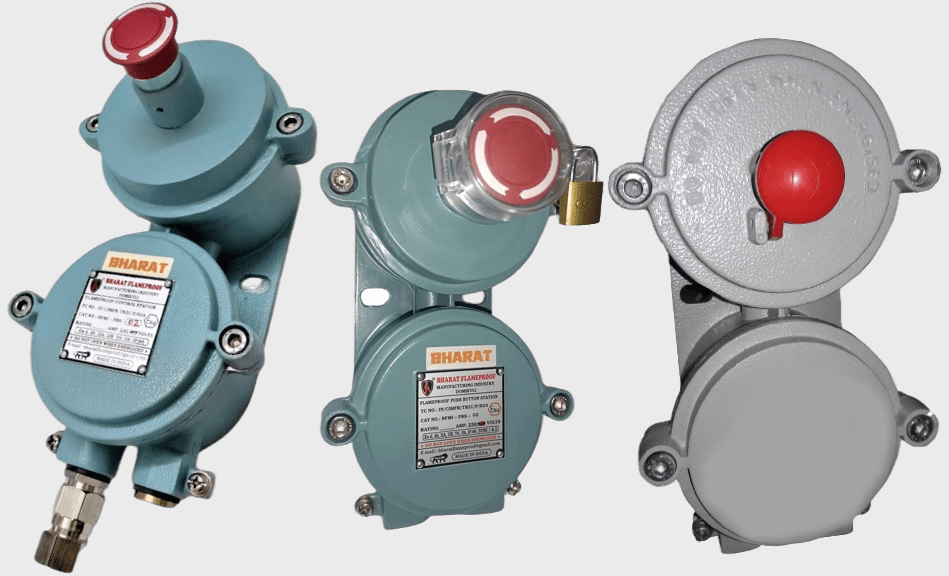

Flameproof Explosion Proof Control Stations are high-temperature resistant and explosion-proof control stations used for various applications. They have a fully ducted and enclosed system with two isolated positions for upper and lower limit switches and two isolated positions for line and load contacts.

At Bharat Flameproof, we’ve been designing and manufacturing flameproof control stations for over a decade. Our control stations are made from premium cast aluminum alloy LM6 and are suitable for use in flameproof zones 1 and 2.

Our wide range of flameproof control station products is known for their precision-engineered design and excellent function. All of our junction boxes cover gas groups: IIA, IIB, and IIC as per IS/IEC 60079-1:2007.

Our quality control designs have been praised by clients for their durability and versatility. Control stations can be either manual or automatic, making them perfect for any location. Their damage resistance means they can be used anywhere without worry. Control stations also promote ease of use with their simplified controls and clear mode of operation.

Features:

- Quality-tested

- Convenient to install

- Easy to maintain

We pride ourselves on the quality of our products and that is only made possible by our team of expert professionals who hold a vast experience and depth of knowledge in their respective domains.

Push Button Station Start And Stop

Rotary Switch

Flameproof Push Button Station Only Off

Our Flameproof Control Station Range

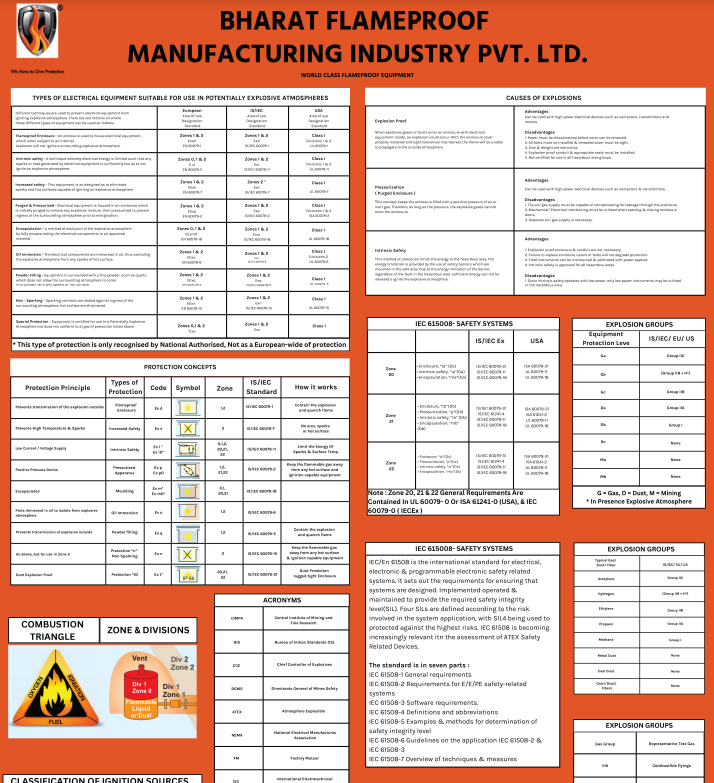

Comprehensive Guide to Flameproof Manufacturing Standards

Testimonials

FAQs

Flameproof explosion-proof control station, is a type of electrical control panel. These are specifically designed to be able to withstand sudden changes in pressure and also the effects of a blast. These explosion proof control panels are used in industrial and mining applications where flammable or combustible materials are present.

Flameproof explosion-proof control stations are important to have in zones which have high levels of dust and other contaminants, as it can easily clog and/or damage the standard regular electrical control panels. The flameproof explosion-proof control stations are susceptible to pressure changes and can help avoid any foreseeable damage within hazardous environments. They are a must for maintaining safety in high-risk areas.

There are different types of flameproof explosion-proof control stations available, which vary based on the level of protection they provide. They are made from inherently flameproof and explosion proof material, so as to limit any damage that can occur through electrical faults. General control panels are prone to getting damaged by pressure changes and also get clogged by dust and other contaminants.

Materials like stainless steel, aluminum and glass-reinforced polyester, are used for making flameproof explosion-proof control stations. These materials are specifically chosen for their ability to resist flames and explosions, especially in hazardous environments. These flameproof explosion-proof control stations help to protect people and property from the devastating effects of explosions and fires.

International safety standards, such as ATEX, IECEx and Ul, need to be adhered to, especially for flameproof explosion-proof control stations. These certifications ensure that the control stations are designed in line with the safety guidelines and are fit to be used in high-risk environments.

Flameproof explosion-proof control stations generally cost slightly more than the regular control stations, because they have more specialized designs. Along with these specialized designs, the size and complexity of the control stations and use of specific materials become the defining factors of the costs of the flameproof explosion-proof control stations. The added safety that is provided by these explosion-proof control stations, makes them worth the investment especially in hazardous environments.