The author of this blog, Ramdas , is an expert writer in the field of flameproof technology and innovation. He has done extensive research to bring the facts about choosing suitable industrial fans to help out readers.

Industrial ventilation systems are necessary for the well-being of people working in factories, warehouses, or any other large structures. This is because they maintain the quality and temperature of air. Selecting the right type of industrial fan is critical for safety, compliance, and industrial efficiency.

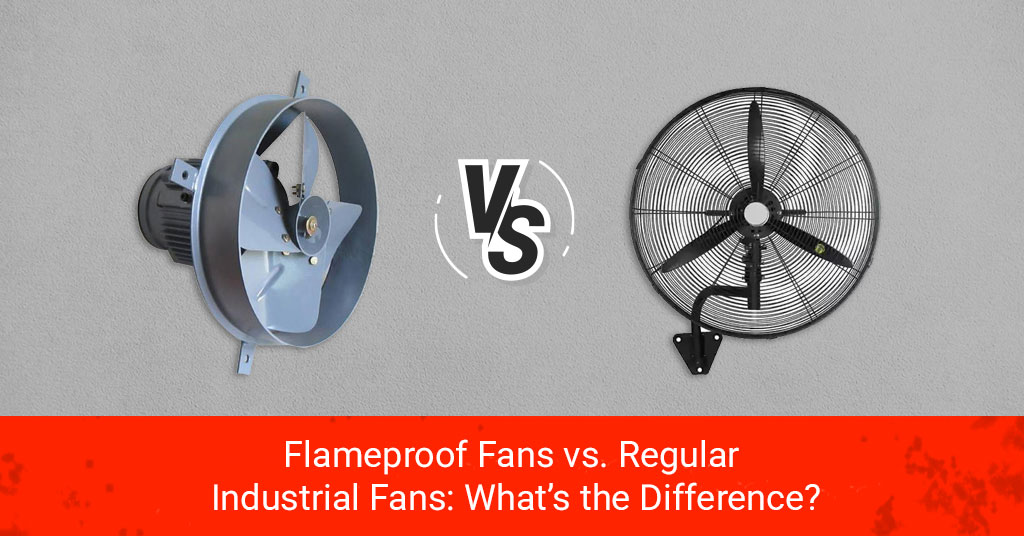

Two types of industrial fans are common in the market today. These are normal regular industrial fans and flameproof fans. Although both are used for air movements such as circulation, cooling, and ventilation, they have different applications.

It’s important to grasp the distinction between these types of fans when working in high-risk areas with hazardous gases, dust, or even chemicals. This article examines some of the differences between flameproof and normal industrial fans to assist you in making the best decision regarding your facility.

What are Industrial Fans?

Fans manufactured for factory, workshop, or commercial use are termed industrial fans. As the name suggests, these are heavy-duty air-moving devices used for air movement in the fans for circulation, cooling, and the removal of fumes, dust, and heat. Furthermore, these devices can be subdivided into different types, including but not limited to Industrial exhaust fans, turbo fans, industrial fan ventilators and industrial fan roof mounted.

The majority of common industrial fans are made to assist in ventilation and cooling. They contain powerful motors and specially designed industrial fan blades made to enable high airflow. Nonetheless, they are not appropriate for areas that contain dangerous combustible gases, dust, or vapours, as they do not have any means that would prevent ignition.

Understanding Flameproof Fans

Flameproof fans are those designed to withstand hazardous environments with increased flammable gases or vapours. They are constructed in such a manner that avoids the chances of a spark, heat, or any electrical fault causing a fire or explosion.

Chemical plants, oil refineries, and gas storage facilities widely make use of these fans. Their unique feature is specially designed enclosures and motors, which guarantee safety from volatile environments.

What Are Explosion-Proof Fans?

These fans are often confused with flameproof exhaust fans, which is not correct. Both types are aimed at hazardous areas, but these contain and prevent an internal explosion from escaping the fan from spreading.

Combustible dust, paint fumes, or volatile chemicals industries are commonly equipped with these. They are designed to meet stringent safety measures regarding their ability to withstand high-pressure explosions without the risk of flames and heat escaping.

Key Differences: Flameproof vs. Regular Industrial Fans

- Safety Features

- Regular industrial fans do not include protective covers as safety measures. They also do not have spark-resistant features.

- Flameproof fans ensure that neither sparks nor overheating flames are produced in an environment that is flammable.

- Material & Construction

- Blades and motors of regular industrial fans do not qualify as standard because they are not built to withstand blades and are durable.

- Sealed motors with static proof would be the most ideal for flameproof fans. Put them in an explosion-proof case and anti-static coating, and you will have a flameproof fan.

- Application & Usage

- General purpose industry is not an issue for regular industrial exhaust fans for use in warehouses and workshops.

- Flameproof fans are highly needed and necessary in oil refineries, chemical industry plants, and other highly hazardous areas.

- Certification & Compliance

- Regular fans require no certification of any kind.

- Flameproof and explosion-proof fans made in India have to meet the ATEX, IECEx and IS/IEC standards of 60079 and 790.

- Cost & Maintenance

- Cheaper to purchase and maintain is what regular fans are, and easier is the keyword in this section.

- Due to the compliance with safety requirements and special materials, these fans are more expensive, which makes them non-regular fans.

Applications of Flameproof and Explosion-Proof Fans

Where Are Flameproof Fans Used?

- Gas and Oil Refineries

- Chemical Processing Facilities

- Fertiliser Plants

- Battery Charging Facilities

Where Are Regular Industrial Fans Used?

- Logistics and Warehouse Facilities

- Manufacturing Plants (not dangerous)

- Shopping centres and large retail shops

- Catering and food production units

Choosing the Right Fan for Your Needs

Meeting fan selection criteria requires the identification of the industry, place of use, and safety needs. Facilities with flammable gases, vapours, or dust need a flameproof or an explosion-proof fan. On the other hand, if only air circulation and cooling within a safe environment were to be achieved, a regular industrial fan would be adequate.

Things to consider include the following:

- Hazardous vs. Non-Hazardous Environment – Assess the danger of your workspace.

- Ventilation Requirements – Select the type of industrial fan, ventilator exhaust fan, or roof fan according to the need for air circulation.

- Regulatory Compliance – Check if flameproof fans adhere to India’s safety standards.

Conclusion

Flameproof fans and typical industrial fans have specific differences. Both are important for ventilation purposes, but flameproof fans are used only where fire risks are extremely high. On the other hand, typical industrial fans are preferred for general air circulation and cooling purposes. Right fan selection provides safety, efficiency, and compliance within the workplace from many angles.

Facilities operating within hazardous environments need to ensure compliance with safety laws. This makes purchasing flameproof or explosion-proof ventilation systems or fans from brands like Bharat Flameproof indispensable. Looking to buy high quality flameproof fans for your facility? Check out Bharat Flameproof.

FAQs

Flameproof fans do not allow the ignition to cause any spark or heat, and explosion-proof fans prevent an internal explosion from spreading out.

Not all industries, only those which have chemical plants, oil refineries, gas storage units, and those which are more hazardous, require flameproof fans.

Regular industrial fans do not have the construction made for flammable dust or gasses, making them hazardous to certain conditions.