A junction box is a container or enclosure designed to house electrical connections. It serves as a protecting hub for electric connections from environmental factors and preventing any potential dangers.

A Flameproof junction box takes this idea a step ahead. They are specially engineered to function in dangerous environments wherein the presence of flammable gases or dirt ought to pose a significant hazard.

Understanding Flameproof Junction Boxes

These specialised junction box containers are built with strong materials and are designed to withstand internal explosions. In the event of an explosion inside the enclosure, flameproof junction box packing containers save the explosion from propagating to the surrounding surroundings, safeguarding personnel, tools, and manufacturing units.

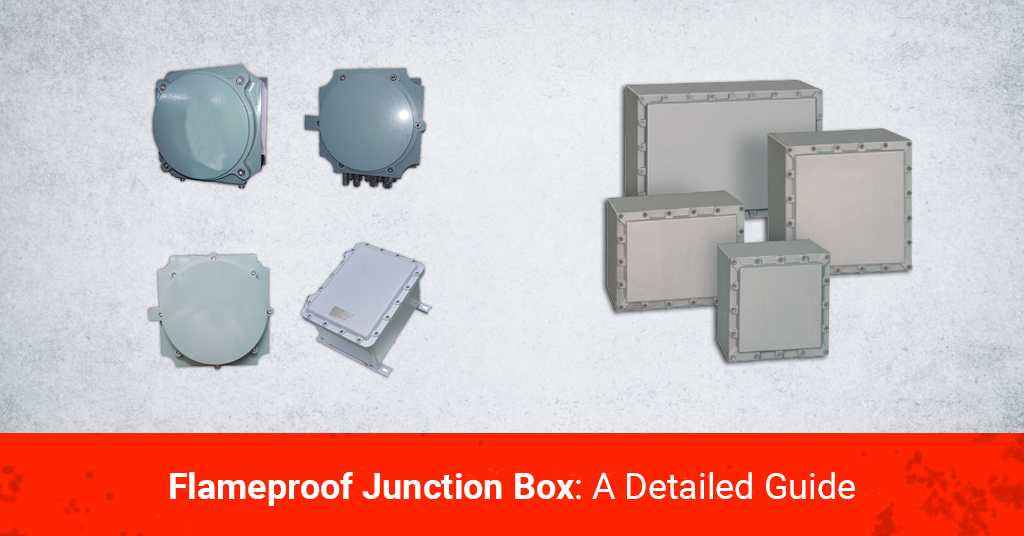

Types of Junction Boxes

The junction box is available in various kinds, with each one serving a unique purpose. The most usual kinds include:

Standard Residential Junction Box

Standard residential junction boxes, often preferred for their straightforward wiring, are mostly utilised in houses and small enterprise units. These containers are usually small and house the primary wiring from the main power supply, featuring cautiously prepared wiring to ensure electric protection. Due to their length, standard residential junction boxes offer enough area to save cord overlap.

Round Pan Electrical Junction Boxes

Round pan junction box containers resemble pans in form and are generally ¾ inch deep. They are best for incorporating electric lighting fixtures into ceilings or walls in residential settings. This steel junction box container is regarded for its reliability in twine isolation throughout a residence. The wiring inside the round pan junction box is well-organised to upkeep circuit safety. Given their smaller length, it is crucial not to overload the wiring device to avoid any dangers.

Outdoor Junction Box

Outdoor junction boxes are specialised enclosures designed to house the whole electrical connection for a particular building. They function as a significant hub for wires connecting the building to the power supply on the road. Constructed from durable materials, typically metals, these boxes are built to withstand damage and shield the wiring from the elements.

Octagon Junction Box

Octagon junction boxes feature an octagonal shape that makes them appropriate for numerous electrical uses within a house. Commonly mounted on ceilings, these boxes provide ample area for advanced wiring whilst taking up minimum room.

Components of a Flameproof Junction Box

A flameproof junction box is composed of numerous key additives, each serving a particular function:

- Enclosure: The enclosure is the outer shell of the junction box, constituted of sturdy materials to withstand harsh environmental conditions and capability explosions.

- Gland Plates: Gland plates are used to create a secure seal around cable entries and prevent the ingress of flammable gases or dirt.

- Cable Glands: These are used to steady and protect the cables entering the junction box. They offer a seal to keep the flameproof integrity of the enclosure.

- Terminal Blocks: Terminal blocks are where electrical connections are made inside the junction box. They provide a secure and organized manner to connect wires and cables.

- Sealing Compound: A sealing compound is used to seal gaps and ensure the integrity of the junction box, preventing the escape of gases or dust.

Which Industries Use Flameproof Junction Boxes?

The Flameproof junction box finds applications in diverse industries where the risk of explosions and risky environments is a consistent problem. In India, industries that commonly rely on flameproof junction box containers encompass:

- Oil and Gas: The oil and gas enterprise uses flameproof junction box containers significantly, especially in drilling rigs, refineries, and production centres where flammable gases are conventional.

- Chemical and Petrochemical: Facilities involved with the production and storage of chemicals and petrochemicals require a flameproof junction box to guard against explosions.

- Pharmaceuticals: Pharmaceutical manufacturing involves the use of numerous solvents and chemicals, making flameproof junction box containers crucial for ensuring protection and compliance.

- Mining: In mines wherein the presence of explosive gases or dust is commonplace, the flameproof junction box are used to decrease the danger of ignition.

- Power Generation: Power units, including thermal and gasoline-based facilities, require flameproof junction box containers to ensure the safety of electrical systems.

- Automotive: Paint booths and centres dealing with risky automobile materials utilise the flameproof junction box to prevent hazards.

Choosing the Right Flameproof Junction Box

Choosing the best flameproof junction box field is pivotal for protection and operational performance. Here are key elements to recall:

- Hazard Zone: Start identifying your facility’s hazard zone class (Zone Zero, Zone One, or Zone Two) to decide the perfect junction box type.

- Material Choice: Opt for a junction box made from materials properly ideal for your facility’s environmental conditions, ensuring corrosion resistance and resilience to temperature fluctuations.

- Capacity: Ensure the junction box container offers sufficient space and functionality to deal with cables and connections successfully.

- Certifications: Confirm that the junction box container holds certifications from government authorities to ensure compliance with safety requirements and rules.

- Customisation: If needed, choose a producer capable of imparting custom answers to fulfil your precise requirements.

Benefits of Flameproof Junction Boxes

A Flameproof junction box has several benefits including but not limited to:

- Increased Safety: The first and foremost advantage of a flameproof junction box lies in its ability to strengthen protection in unsafe environments. They effectively mitigate the danger of explosions spreading, as a consequence lowering the possible damages.

- Compliance: Using a flameproof junction box helps industries comply with safety guidelines, minimising the risk of injuries and regulatory penalties.

- Environmental Protection: Flameproof junction box containers prevent the release of hazardous materials, minimising the capacity for environmental damage and pollution.

- Versatility: The junction boxes are customised to fulfill particular enterprise necessities, ensuring comprehensive protection in opposition to capability hazards.

Conclusion

In a country as diverse and industrially vibrant as India, prioritising safety and strict compliance with safety regulations is of extreme importance.

One vital issue in facilitating safety in numerous industries is the thorough knowledge and right implementation of flameproof junction box containers. These specialized enclosures serve as a linchpin for shielding not only the employees and equipment but also the encompassing environment, specifically in hazardous settings.

To know more about the various applications of flameproof products, read our detailed blog- Common Applications of Flameproof Products in Various Industries

The Flameproof junction box is ingeniously designed to provide a sturdy and effective solution for mitigating risks in excessive-risk environments. By carefully deciding on the ideal kind of junction box and diligently adhering to protection requirements, industries can appreciably enhance their safety protocols.

By investing in flameproof junction box containers, industries can ensure uninterrupted continuity in their operations. This system lowers disruptions, reduces downtime, and ultimately, improves productivity.

Beyond operational advantages, these specialized enclosures additionally replicate a corporation’s dedication to responsible enterprise practices. They exhibit a dedication to the well-being of personnel, the maintenance of valuable systems, and the safety of the environment from probable injuries in high-risk business settings.

In essence, the flameproof junction box is not simply an optionally available protection function but also serves as a bulwark against the formidable demanding situations posed with the aid of operating in dangerous environments.

They encapsulate an organization’s dedication to the highest protection requirements, making them an essential factor in business safety strategies in India and across the globe.

FAQs

A flameproof junction box is designed to operate in dangerous environments and might contain inner explosions, stopping them from exploding outside. Standard junction boxes do not offer this level of protection.

Flameproof junction boxes are essential to defend against the danger of explosions in environments with flammable gases or dirt, ensuring the safety of personnel and devices.

A flameproof junction box generally includes an enclosure, gland plates, cable glands, terminal blocks, and a sealing compound.