In this blog, we will understand The Role Of Flameproof Distribution Boards In Electrical Systems

Let’s begin!

Safety is paramount in areas where explosions and fires may occur. These dynamic and high-energy environments demand strict measures to safeguard lives as well as property.

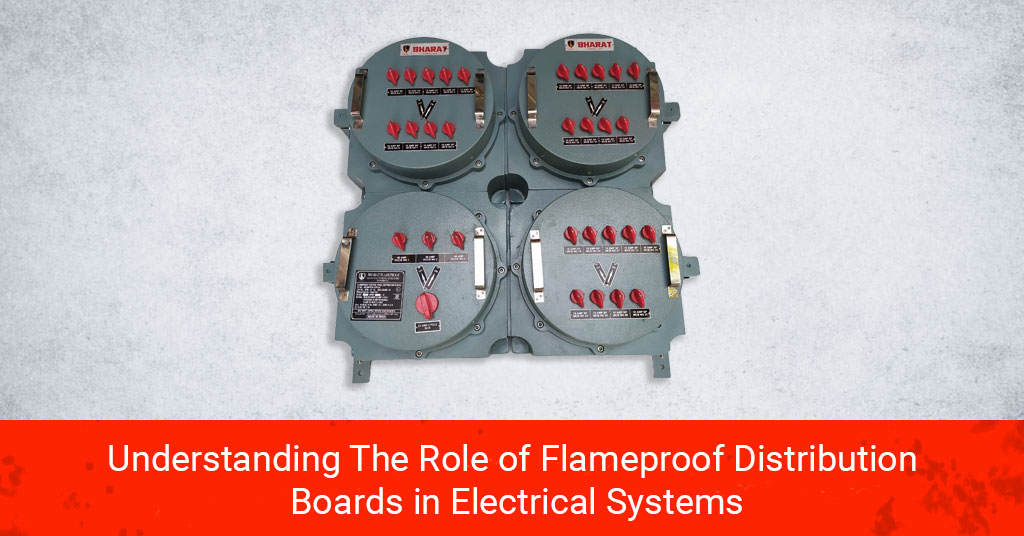

In the heart of this vigilant landscape lies the unsung hero – Flameproof Distribution Boards.

Industrial areas are protected by flameproof distribution boards. Ignorance of safety in such places always comes with great cost. It ranges from employee ailments to environmental and legal problems that face the industry. Compliance with the set standards and using flameproof distribution boards is a proactive means to ensure a protected workplace.

Let’s delve into the essential components, design considerations, safety standards, and the myriad benefits that make these boards indispensable for secure operations.

Components and Design

Flameproof distribution boards are commonly made of glass-reinforced polyester, aluminium, and stainless steel. These materials have features that minimise electrical malfunction-induced damage and prevent fire outbreaks or explosions. It also prevents fire outbreaks and explosions. These safety measures have their effectiveness and strength collectively contributed to by these components:

- Enclosures: Their potentially explosive materials made cloth in materials with substances restricted within.

- Circuit Breakers: Faults interrupting electrical current which is done faster by circuit breakers specifically designed for this purpose, thus preventing overheating and reducing fire risk.

- High Durability: These boards can last, being able to hold so much; thus, they can be used for a long time.

- Easy Installation: It is easy to set up these superhero boards; hence, the process of installation is fast and without any problems.

- Longer Service Life: Unlike ordinary boards, these superheroes have a longer span on earth that results in increased dependability and service life in general.

- Gas Group IIA, IIB, IIC: Like detectives for safety, such gasboards are ready to keep the workplace safe from various types of gases(IIB, IIC), just as in the case of an accident.

- Weatherproof (IP66): They are like all-weather superheroes, so their weatherproofing makes them strong even when subjected to harsh conditions(IP66).

- Finish: Light Grey to Shade 631: With a stylish light grey finish that adds sophistication to industrial safety, these conveniently designed superhero boards look sleek and professional.

- Gasket: Neoprene: A Neoprene gasket acts like a suit of armour for the comic book hero who wears it; this means nothing will get out or come inside.

- Monitoring Devices: Real-time temperature readings, as well as information about current flow, among other things, from sophisticated monitoring devices, enable early interventions before major problems arise.

- Compliance with Standards: Each component conforms to industry safety rules, thus ensuring consistency, reliability, and performance that meets or even surpasses regulatory requirements.

Safety Standards and Compliance

In the midst of this electrifying industrial dance, safety is centre stage, with explosion-proof distribution boards as the curtain raiser. Imagine these constituents as a concert given by professionals who overcome dangers in their path with good timing. These elements are built to harmonise with each other, like lead dancers in ballet.

Certifications such as UL, ATEX, and IECEx can keep manufacturers from violating any global explosion-proof distribution board safety standards. These certificates aren’t only about security but also represent high-class standards in times of danger.

- Compliance Assurance: Observation of safety rules leads to careful designing of flameproof distribution boards that comply with or surpass industry standards.

- Enhanced Safety Levels: Compliance first assures robust safety for people and property where explosions or fires are bound to occur.

- Meticulous Design: The website highlights detailed design beyond what is expected by the regulations in engineering distribution boards.

- Operational Confidence: Focus on safe standards brings confidence in the reliability of fireproof distribution boards for secure industrial operations.

- Effective Containment: Compliant materials make distribution boards to contain explosive reactions securely, hence ensuring safety.

- Secure Operational Landscape: It ensures that even if it is hazardous, the distribution board will work well as per the available information on its website.

Benefits of Flameproof Distribution Boards

Normal devices can easily catch fire and get damaged. On the one hand, the Flameproof Distribution Boards outperform normal shields, making sense to install such boards, which are always prepared for unexpected dangers at work.

- Reliability Redefined: These panels have the ability to redefine themselves and hence remain highly predictable in performance, especially at the most critical of times.

- Uninterrupted Operations: Designed attributes, together with certifications, validate the smoothness of flow within an industry, thereby cutting down stoppages.

- Reduced Downtime: Less procrastination means a lesser expenditure, thus a cost-effective mode of business operation.

- Proactive Risk Mitigation: These panels go above expected levels in addressing safety concerns concerning fast-changing sectors.

- Cost Reduction: They result in cost savings in the long run by preventing costly repairs and reducing downtime.

- Plasticity: Manufactured to resist diverse conditions, these boards are versatile for a variety of industries and applications.

- Greenness: Accordingly, these boards reduce fire outbreaks while minimizing damage, aid sustainability, and lower environmental impacts.

Conclusion

Summarising what has been covered so far in this blog reiterates the importance of flameproof distribution boards for ensuring safety in hazardous environments. This helps industries embrace these boards, which not only prioritize safety but also harden their electrical systems against future risks, thereby establishing a strong and secure operational framework.

Are you interested in learning more about flameproof distribution boards tailored to your industry? Check out Bharat Flameproof, a leading provider of safety-focused solutions. Get our expertise for enhanced industrial safety standards and uninterrupted operations amidst dangerous surroundings.